1. Power and impedance matching

Power matching

The rated power of the amplifier should be slightly greater than the rated input power of the speaker (recommended 1.5-2 times) to avoid clipping distortion due to insufficient power ("clipping distortion" will burn the speaker coil).

For example, if the rated power of the speaker is 50W, the amplifier power is recommended to be 75-100W.

Impedance matching

Make sure that the output impedance of the amplifier is consistent with the impedance of the speaker (such as 8Ω). If the amplifier impedance (such as 4Ω) is smaller than the speaker (such as 8Ω), the output power will be halved; otherwise, the amplifier may be burned.

2. Heat dissipation management

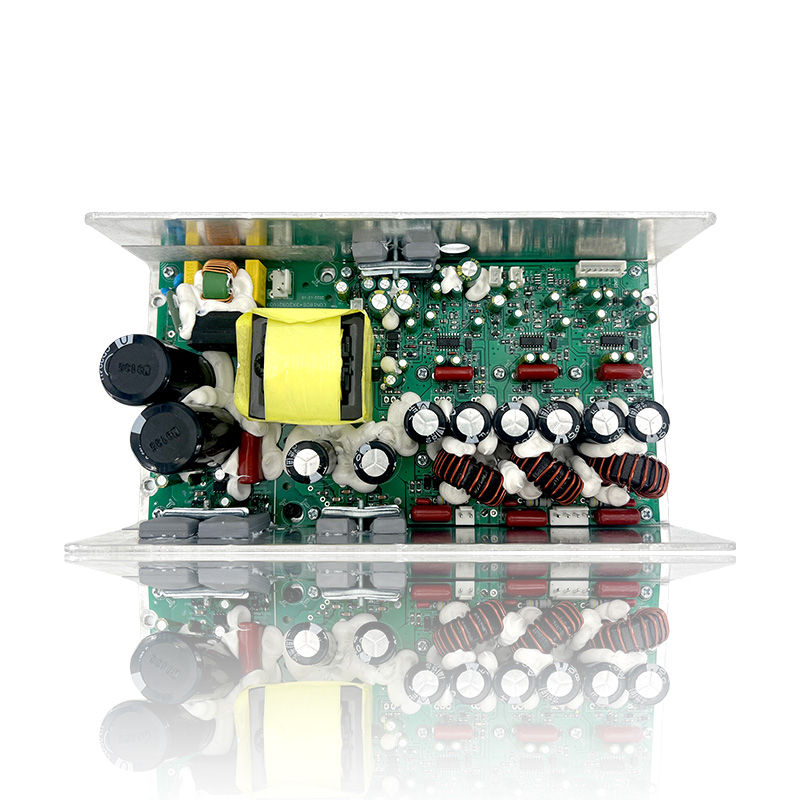

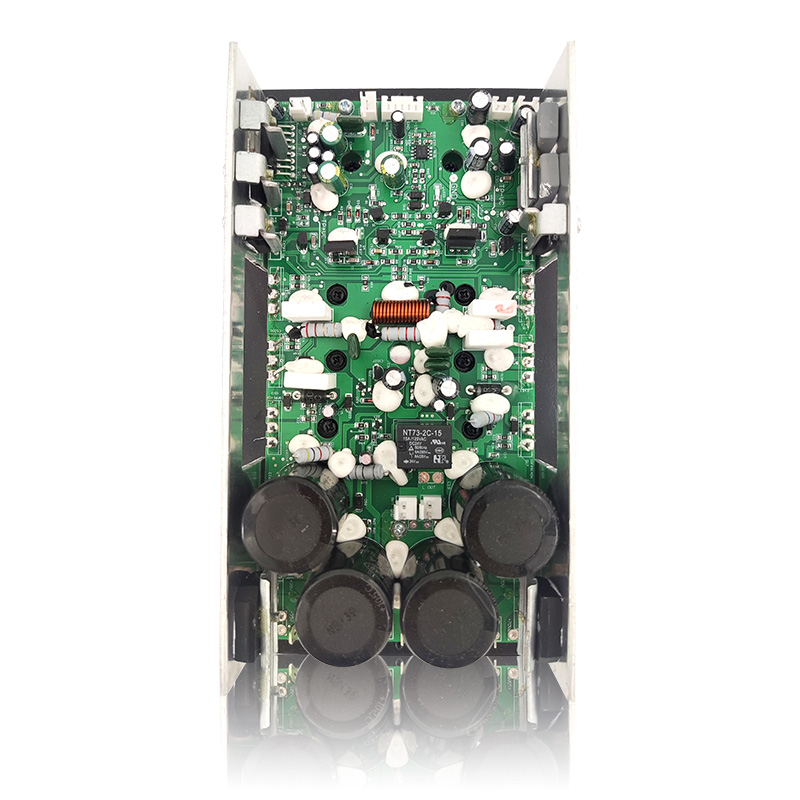

Heat dissipation design

The efficiency of Class AB Loudspeaker Amplifier is about 50%-78%, and the remaining energy is converted into heat. It is necessary to equip it with sufficient heat sinks (such as aluminum fins) or forced air cooling to ensure that the chip temperature is ≤85℃.

Thermal resistance calculation example: If the ambient temperature is 50℃ and the amplifier power consumption is 18.85W, the heat sink thermal resistance must be ≤5℃/W (θja=θjc+θsa).

Avoid thermal runaway

The static bias current must be stable to prevent current drift caused by temperature rise. A negative feedback circuit or temperature compensation diode (such as D1/D2 bias) can be used.

3. Circuit design and debugging

Eliminate crossover distortion

Class AB Loudspeaker Amplifier is prone to crossover distortion when the signal is small. The bias voltage (such as diode bias or current source bias) must be accurately set to make the transistor slightly turned on when the signal is zero.

Anti-oscillation measures

Add an RC vibration elimination circuit (Joubert network, such as 1Ω resistor + 0.1μF capacitor) to the output to suppress high-frequency oscillation. Add compensation capacitors (such as 10pF) to the feedback loop to ensure that the closed-loop gain is ≥10 times to enhance stability.

4. Power supply and grounding

Power supply filtering

Use low ESR electrolytic capacitors (such as C5/C6) close to the power pins to reduce ripple noise. Digital and analog power supplies need to be filtered independently.

Grounding optimization

The input signal ground and output signal ground are routed separately, and finally connected to the ground terminal of the power filter capacitor at a single point to avoid noise introduced by the ground loop.

5. Use and maintenance

Avoid overload and short circuit

Connect a fuse or current limiting resistor (such as 0.5Ω) in series at the output end to prevent short circuit damage to the amplifier.

Regular inspection

Check the cooling fan, capacitor bulging and solder joint aging every 6 months, and replace failed components in time (such as the life of electrolytic capacitors is about 5 years).

English

English Español

Español 中文简体

中文简体