Class AB loudspeaker amplifiers are highly regarded for their perfect balance between sound quality, efficiency, and heat dissipation. They possess the low distortion and high fidelity of Class A amplification and the higher efficiency of Class B amplification. However, this design also brings an unavoidable byproduct—heat. Therefore, regular internal cleaning and maintenance of Class AB loudspeaker amplifiers are crucial to ensuring their sound quality.

1. The Core Enemy: The Impact of Heat

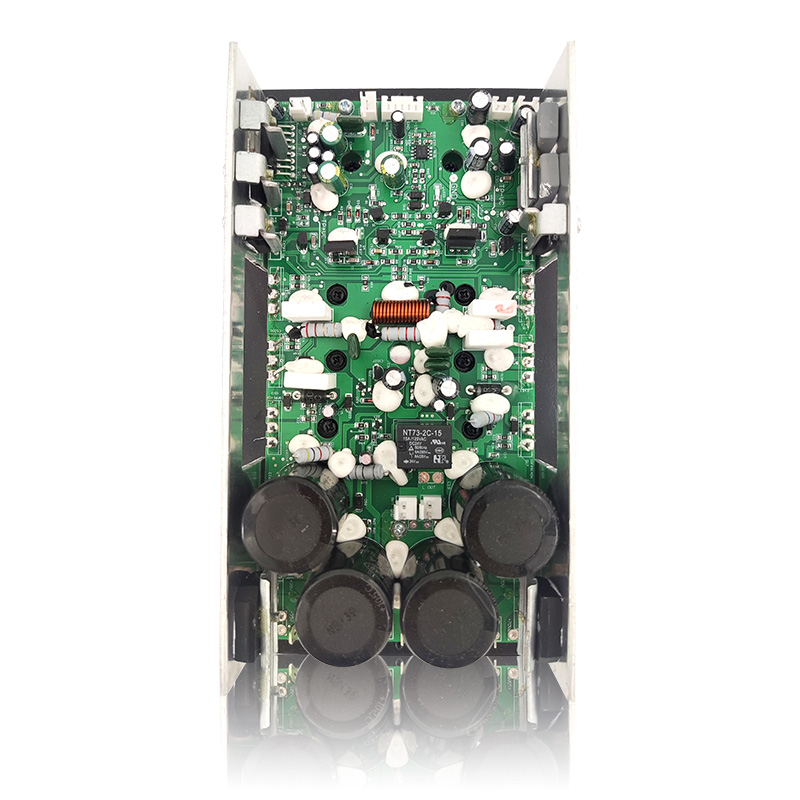

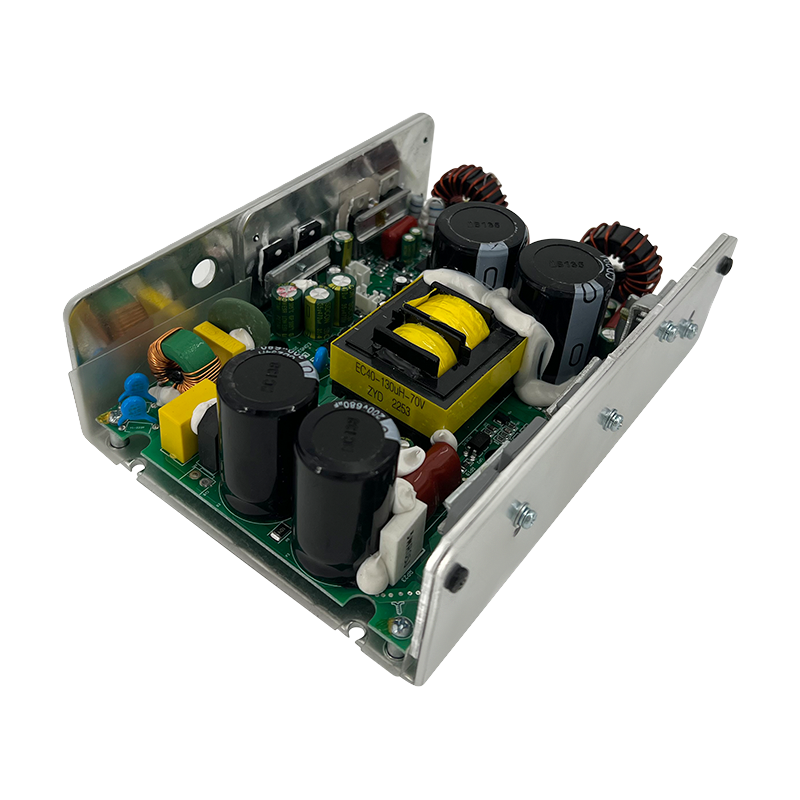

Even without a signal output, the output stage power transistors of a Class AB amplifier retain a certain amount of quiescent current during operation, generating continuous heat. This is a characteristic that distinguishes it from pure Class B amplifiers and is the source of its superior sound, but heat also becomes the most critical factor to manage.

Decreased Heat Dissipation Efficiency: Dust as a “Heat Blanket”

Problem: Amplifiers rely on heat sinks and fans (if present) to quickly dissipate the heat generated by the power transistors into the air. Dust and lint accumulate between the fins of the heat sink, forming a heat-insulating layer that severely hinders airflow and heat exchange.

Consequences: Reduced heat dissipation efficiency leads to abnormally high temperatures in the power transistor and heatsink. When transistors operate under overheating conditions, their parameters drift, causing a sharp increase in total distortion (THD) and deteriorating sound quality.

Triggering thermal runaway, leading to permanent damage.

Problem: Power transistors have a negative temperature coefficient, meaning that higher temperatures result in better conductivity. This leads to further increases in current, generating more heat and creating a positive feedback loop.

Consequences: If heat dissipation is inadequate and the temperature exceeds a critical point, this loop will spiral out of control, ultimately burning out expensive high-power transistors within seconds or even milliseconds, and potentially affecting surrounding components such as resistors and diodes, causing catastrophic and costly failures.

2. Preventing Electrical Faults and Ensuring Stable Operation

Besides heat, dust itself can directly cause electrical problems.

Potential Threats to Circuit Boards and Components

Problem: Dust in the air has a certain degree of hygroscopicity (especially in humid environments), accumulating on high-voltage, high-current circuit boards.

Consequences:

Leakage and Short Circuit: Damp dust can reduce the insulation resistance between different points on the circuit board, generating slight leakage current. This not only increases noise but can also cause high-voltage arcing or partial short circuits, burning out the circuit.

Corrosion: Chemicals in dust can accelerate the oxidation and corrosion of metal solder joints and pins on the circuit board, leading to poor contact or open circuits.

Protection and Adjustment Circuits

Problem: If precision adjustable resistors inside the amplifier (such as potentiometers used to adjust bias current and DC offset) are covered with dust, it may cause poor contact.

Consequences: Bias current imbalance prevents the amplifier from operating in its optimal Class AB state. It may bias towards Class A, causing a surge in heat, or bias towards Class B, resulting in crossover distortion and a rougher sound quality. Simultaneously, dust may also affect the normal operation of sensors in protection circuits (such as overcurrent, overheat, and DC protection), preventing them from triggering correctly at critical moments.

3. Maintain Optimal Sound Quality

Maintain Low Distortion and High Signal-to-Noise Ratio

As mentioned above, overheating and bias current misalignment directly lead to increased harmonic and crossover distortion, making the sound harsh and rough. Dust-induced leakage introduces additional background noise (hissing or humming), reducing the overall signal-to-noise ratio and compromising the purity of the music.

Ensure Dynamics and Power Output

An amplifier that is constantly exposed to high temperatures due to poor heat dissipation will experience accelerated degradation of its components' lifespan and performance. As a self-protective mechanism, it may be unable to provide ample, transient high current output, resulting in a "weak" sound and lack of impact during dynamic music.

4. Extend Equipment Lifespan

Comprehensive Benefits: Regular internal cleaning (using professional tools such as a hairdryer and soft brush), and taking this opportunity for a professional to inspect and recalibrate the quiescent bias current, ensures that all components always operate within their designed temperature and electrical ranges.

Long-term value: This can significantly delay problems such as electrolytic capacitor aging and power transistor performance degradation, thereby extending the equipment's lifespan by several years or even decades, protecting your investment. A classic machine in good condition also has higher collectible and usage value.

English

English Español

Español 中文简体

中文简体